We are committed to farmers.

To work hand in hand and get the vegetables processed at the right time, we take care from the seed to the final product, always offering the best quality and always using Spanish origin.

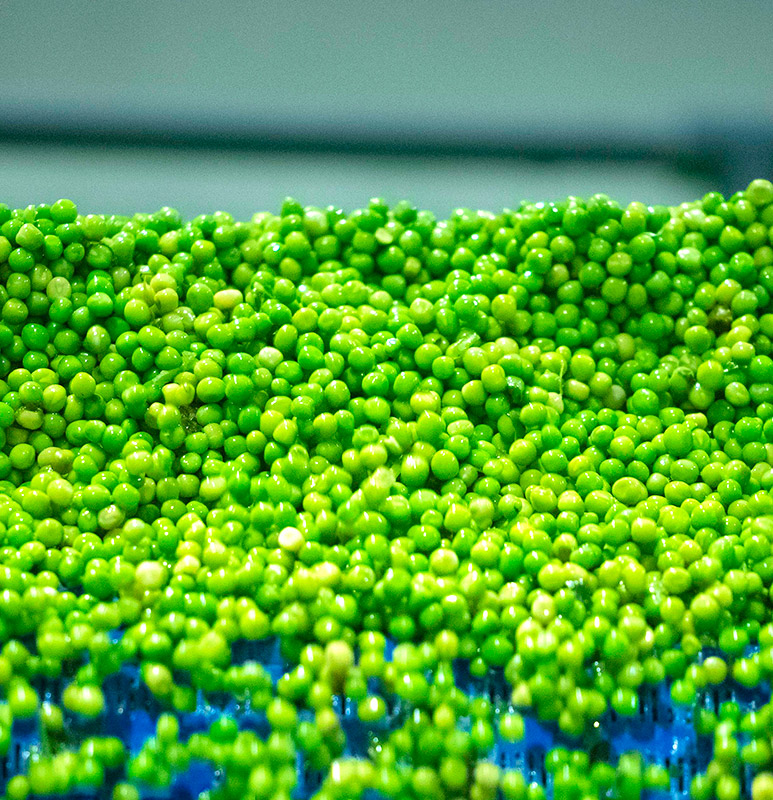

Newly created company, dedicated to the processing and sale of frozen vegetables. We ultra-freeze using the IQF method, to obtain vegetables and fruits that maintain their nutritional and organoleptic characteristics (color, smell, taste and texture) as well as a long shelf life. By freezing quickly, we obtain healthy products with great advantages for our customers. The production process is carried out integrally in the factory located in Albacete.

Congelados Pedaneo has an annual production of 16,000 tons of IQF finished products, involving the processing of more than 20,000 tons of raw material. The main products are: pepper, broccoli, onion, cauliflower, zucchini and eggplant.

JNG-BIO has an annual production of 12,000 tons of IQF products, with its own crops and with associated farmers of more than 500 hectares in organic agriculture throughout Spain, as well as 200 hectares for Baby Food. Its main products are: organic peas, organic broccoli, organic corn, organic onions and organic peppers.

FRDP has an annual production of 22,000 tons of organic IQF product, processing more than 31,000 tons of raw material. Produced in Spain (through JNG-BIO), France, Belgium and Holland, its product range includes more than 100 references of organic products all in IQF.

Due to the high demand of the products, the lack of production capacity and the annual growth, the three companies have strategically joined together, forming a company that will be specialized in products such as: peas and sweet corn, but also focused on production. Growth of each company, making a growth plan for the factory located in Albacete, a strategic place in Spanish agriculture.

To work hand in hand and get the vegetables processed at the right time, we take care from the seed to the final product, always offering the best quality and always using Spanish origin.

100% of the control is carried out by the company’s own staff at all stages of production. Control is carried out from the selection of seeds, choice of fields, advice for farmers, collection and transport of the raw material to the facilities in Albacete for processing.

In the factory there are complete lines for: peas, corn grains, broccoli, cauliflower, onion, zucchini, and pepper.

The positioning of the facilities and the proximity to the crops allows the vegetables to be processed in a very short time, ensuring the high quality of the final product.

There are two maintenance warehouses for IQF, temperature controlled -20ºC with a capacity of 3800 pallets and a cold maintenance chamber for 2-8ºC.

The purchase of the Horticola Albacete S.A. factory is not the only investment to be made; due to the high quality standards and demands of our customers, a modernization plan has been implemented for the processing lines and facilities, for the proper treatment of raw material with the objective of being able to differentiate in the market for the high quality products that will be offered.